CIPS L4M2 Defining Business Needs Online Training

CIPS L4M2 Online Training

The questions for L4M2 were last updated at Feb 22,2026.

- Exam Code: L4M2

- Exam Name: Defining Business Needs

- Certification Provider: CIPS

- Latest update: Feb 22,2026

Which of the following is the new technology that has impact on manufacturing sector?

- A . Social Media

- B . E-commerce

- C . Robotics

- D . Blockchain

Sealines Inc is developing its fleet of cargo ships. The company is planning to build a new ship powered by natural gas. Brian, the procurement manager at Sealines, suggests the project team to develop a through-life specification before engaging with the supplier.

Is this a correct approach?

- A . Yes, decommissioning and disposal costs will not be accounted in this approach

- B . Yes, this approach will lower the total cost of ownership

- C . No, a ship is used only once, through-life management is unnecessary

- D . No, the company just needs to select the lowest bidder

Sealines Inc is developing its fleet of cargo ships. The company is planning to build a new ship powered by natural gas. Brian, the procurement manager at Sealines, suggests the project team to develop a through-life specification before engaging with the supplier.

Is this a correct approach?

- A . Yes, decommissioning and disposal costs will not be accounted in this approach

- B . Yes, this approach will lower the total cost of ownership

- C . No, a ship is used only once, through-life management is unnecessary

- D . No, the company just needs to select the lowest bidder

Sealines Inc is developing its fleet of cargo ships. The company is planning to build a new ship powered by natural gas. Brian, the procurement manager at Sealines, suggests the project team to develop a through-life specification before engaging with the supplier.

Is this a correct approach?

- A . Yes, decommissioning and disposal costs will not be accounted in this approach

- B . Yes, this approach will lower the total cost of ownership

- C . No, a ship is used only once, through-life management is unnecessary

- D . No, the company just needs to select the lowest bidder

Sealines Inc is developing its fleet of cargo ships. The company is planning to build a new ship powered by natural gas. Brian, the procurement manager at Sealines, suggests the project team to develop a through-life specification before engaging with the supplier.

Is this a correct approach?

- A . Yes, decommissioning and disposal costs will not be accounted in this approach

- B . Yes, this approach will lower the total cost of ownership

- C . No, a ship is used only once, through-life management is unnecessary

- D . No, the company just needs to select the lowest bidder

Sealines Inc is developing its fleet of cargo ships. The company is planning to build a new ship powered by natural gas. Brian, the procurement manager at Sealines, suggests the project team to develop a through-life specification before engaging with the supplier.

Is this a correct approach?

- A . Yes, decommissioning and disposal costs will not be accounted in this approach

- B . Yes, this approach will lower the total cost of ownership

- C . No, a ship is used only once, through-life management is unnecessary

- D . No, the company just needs to select the lowest bidder

Sealines Inc is developing its fleet of cargo ships. The company is planning to build a new ship powered by natural gas. Brian, the procurement manager at Sealines, suggests the project team to develop a through-life specification before engaging with the supplier.

Is this a correct approach?

- A . Yes, decommissioning and disposal costs will not be accounted in this approach

- B . Yes, this approach will lower the total cost of ownership

- C . No, a ship is used only once, through-life management is unnecessary

- D . No, the company just needs to select the lowest bidder

Sealines Inc is developing its fleet of cargo ships. The company is planning to build a new ship powered by natural gas. Brian, the procurement manager at Sealines, suggests the project team to develop a through-life specification before engaging with the supplier.

Is this a correct approach?

- A . Yes, decommissioning and disposal costs will not be accounted in this approach

- B . Yes, this approach will lower the total cost of ownership

- C . No, a ship is used only once, through-life management is unnecessary

- D . No, the company just needs to select the lowest bidder

Which of the following are typically reasons why an organisation implements value analysis? Select TWO that apply:

- A . To determine the value of each component used

- B . To decide whether there will be sufficient surplus funds to reinvest in the business

- C . To shape and manage supply market

- D . To provide an outline business case for the specification

- E . To find cost reduction opportunities by optimising the components used

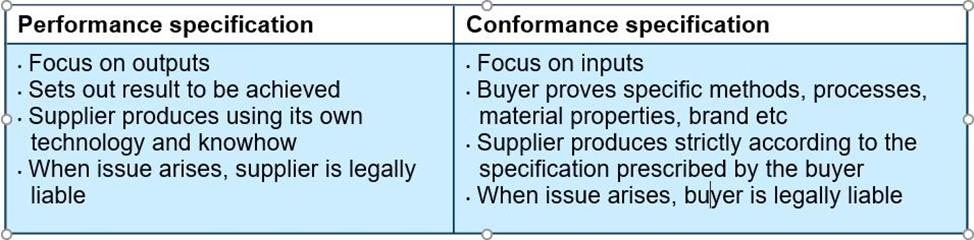

Which type of specification is less time-consuming to develop?

- A . Outcome-based specification

- B . Design specification

- C . Conformance specification

- D . Technical drawings

Latest L4M2 Dumps Valid Version with 144 Q&As

Latest And Valid Q&A | Instant Download | Once Fail, Full Refund