APICS CPIM-8.0 Certified in Planning and Inventory Management (CPIM 8.0) Online Training

APICS CPIM-8.0 Online Training

The questions for CPIM-8.0 were last updated at Jan 02,2026.

- Exam Code: CPIM-8.0

- Exam Name: Certified in Planning and Inventory Management (CPIM 8.0)

- Certification Provider: APICS

- Latest update: Jan 02,2026

Which of the following stock location systems would you use in a repetitive manufacturing, lean environment?

- A . Fixed location

- B . Floating location

- C . Point-of-use storage

- D . Central storage

Which of the following inventory management techniques is most responsive to changes in demand levels?

- A . Two-bin system

- B . Periodic review system

- C . Cycle counting

- D . ABC classification

In a lean environment, the batch-size decision for planning "A" items would be done by:

- A . least total cost.

- B . min-max system.

- C . lot-for-lot (L4L).

- D . periodic order quantity.

Which of the following is the fundamental difference between finite loading and other capacity planning approaches?

- A . It is highly dependent on advanced computer software to function effectively.

- B . It is only managed by shop floor supervisors.

- C . It can use historical information to drive decision-making processes.

- D . It considers adjustments to plans based on planned capacity utilization.

One way to mitigate liability risk in the supply chain is to:

- A . negotiate lower component cost.

- B . require traceability for components.

- C . push inventory to supplier locations.

- D . use less-than-truckload (LTL) shipments more frequently.

How would a master production schedule (MPS) be used In an assemble-to-order (ATO) manufacturing environment?

- A . The MPS is used to plan subassemblies and components; end items are only scheduled when a customer order is received.

- B . Subassemblies are scheduled in the MPS when the customer order is received, and production can start.

- C . Typically, the MPS is not used in companies using an ATO manufacturing strategy.

- D . Often In an ATO environment, the MPS is created once a year and only revised if a product is discontinued.

In Company XYZ, transaction-costing capability has been Integrated into the shop floor reporting system. A batch of 20 units was started in production. At the fourth operation, 20 units are reported as complete. At the fifth operation, 25 units are reported as complete. When all operations are complete, 20 units are checked into the stockroom.

If the error at the fifth operation is undetected, which of the following conditions will be true?

- A . Stockroom inventory balance will be incorrect.

- B . Operator efficiency for the fifth operation will be overstated.

- C . Units in process will be understated.

- D . Work-in-process (WIP) cost will be understated.

If fixed costs are §200,000 and 20,000 units are produced, a unit’s fixed cost is §10. This is an example of:

- A . variable costing.

- B . activity-based costing (ABC).

- C . absorption costing.

- D . overhead costing.

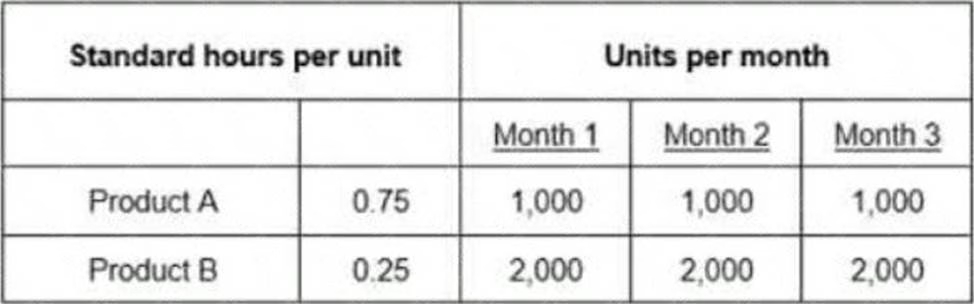

The question below is based on the following information:

Work Center 1 has an available capacity of 1,200 hours per month.

Which of the following amounts represents the cumulative difference between the required capacity and the available capacity of Months 1 through 3?

- A . 50

- B . 150

- C . 1.250

- D . 3.750

In which of the following phases of the product life cycle is product price most effective in influencing demand?

- A . Introduction

- B . Growth

- C . Maturity

- D . Decline

Latest CPIM-8.0 Dumps Valid Version with 150 Q&As

Latest And Valid Q&A | Instant Download | Once Fail, Full Refund